Problem: Welding Fumes

Welding fumes are a mixture of metal fumes and gases produced during welding operations. Welding fumes generally have different compositions and contaminants depending on the base material being welded, base material coatings, and the welding consumables and processes being used.

- Mixture of airborne particles and gasses released or produced by various welding processes

- Composition varies according to the welding process and consumables in which weld fume composition typically contains metal oxides and other metal reaction products, particulate from flux of electrodes and gases produced by UV light like ozone and shielding gases

- Compounds. 90% of weld fume particles come from the welding consumables

- Type and quality of base materials being welded including coatings (ie. oils, rust inhibitors, paint, zinc etc.)

- Finer dust mass such as weld fume is alveolic in nature in which it can accumulate in the lungs and remain in the body

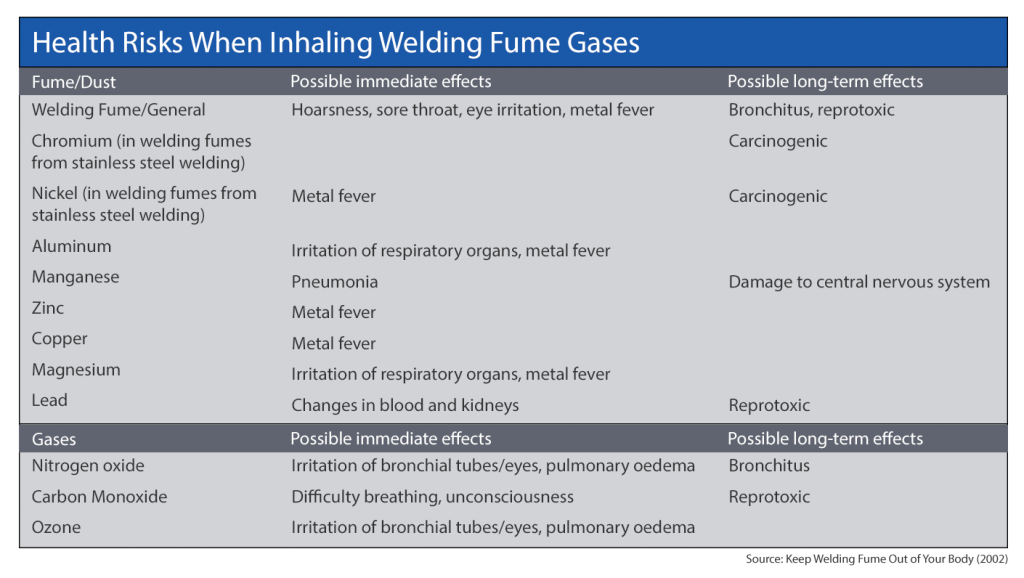

Welding fumes mix with the air we breathe and can enter the human body by inhaling and through the lungs. Exposure to different types of welding fumes may result in different health effects. If a welder inhales gases, fumes, and vapors in large quantities over long periods, this may have a negative effect on his/her health.

Here are some of the health risks associated with breathing in welding fumes:

Solution:

Source capture arms and hoods are generally the most efficient and safest way to capture welding smoke.

Downdraft tables are great for keeping grinding dust and welding smoke out of the breathing zone and factory.

Environmental Diluter Systems.

“Push Pull systems” when Source capture is not feasible.

Fire Stations Products

Fume Tracker Capture Arm

Duis imperdiet at lacus sit amet sagittis. Fusce iaculis nibh vel ex congue, at porttitor turpis commodo. Nulla faucibus vehicula mi, et sodales sem rhoncus quis. Phasellus feugiat elit ut eros rhoncus, sed sagittis nisi vulputate. Vivamus ipsum ante, porta...

Learn More